Add My Company

Add My Company

Automating Testing Procedures with the DewesoftX Sequencer: The Balloon Lift-off Demonstrator

Introduction – why automate testing procedures?

Automated testing has become essential in today’s manufacturing and R&D environments, where repeatability, accuracy, and efficiency are critical.

The DewesoftX Sequencer—part of the powerful Dewesoft data acquisition (DAQ) ecosystem—enables engineers to fully automate test procedures, from setup to data storage and reporting.

In this article, we demonstrate how the Sequencer simplifies and accelerates quality assurance testing through an engaging example: the Balloon Lift-off Demonstrator. Automation has many advantages, including repeatability, reduced human error, and time- and money-saving benefits.

Automation aligns with modern ISO 9001 quality testing procedures.

The power of the DewesoftX sequencer

The DewesoftX Sequencer automates nearly every part of testing, from selecting the test you want to run to opening the corresponding setup file to starting and stopping data acquisition. The Sequencer can even automate test control by sending commands to analog or digital outputs, as well as to other protocols such as Modbus, OPC UA, CAN, and serial interfaces.

Routine tests can be fully automated, enabling them to be operated by people with a wide range of technical backgrounds. Test automation is especially crucial in manufacturing environments, where quality assurance testing is critical to product success, and in testing labs that run routine tests daily.

Real-world example – the balloon lift-off demonstrator

As an example of automating quality assurance testing, Dewesoft built the original balloon demo in the mid-2010s. This demo was built specifically to demonstrate the capabilities of Dewesoft Sequencer in a quality assurance environment for balloon inflation testing. While this demo provided a great tool, it needed an update to showcase Dewesoft’s ever-expanding capabilities and what is now possible. This is where the new Balloon Lift-off demo came into play.

The Balloon Lift-off demo was designed to simulate a hot air balloon taking off. It allows us to showcase the control of multiple facets of a test bench and to collect data on the balloon's performance, the drive motor, the pumps, and the power supply. While inflating a balloon and moving it uphill may sound simple on the surface, it turns out to be somewhat complicated because of the physical properties of latex. As it happens, DewesoftX has the tools and flexibility to handle these variables.

Handling balloon inflation dynamics

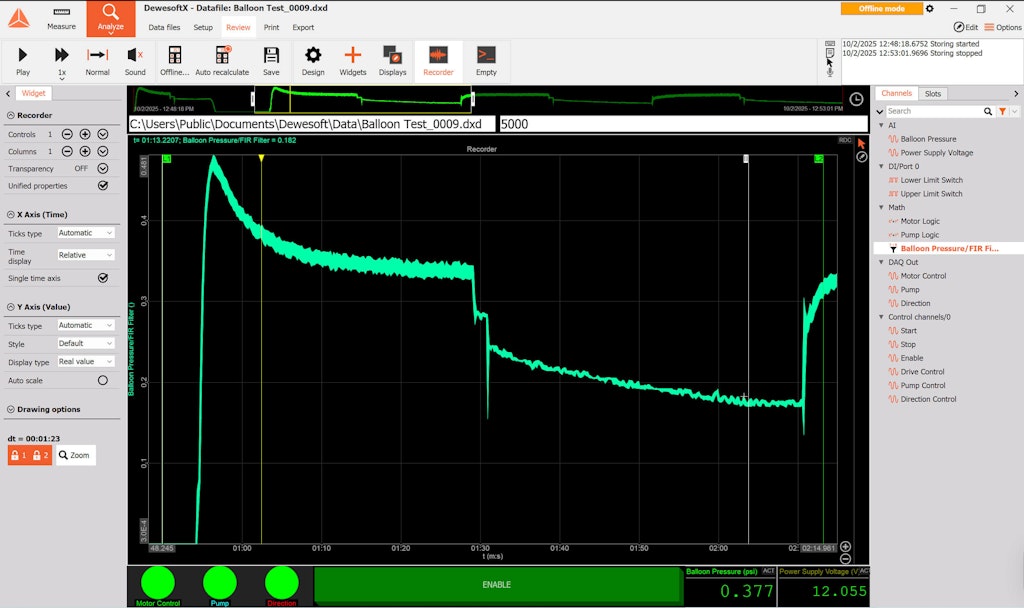

Balloons do not inflate linearly. The DewesoftX recorder screen shown below shows the pressure curve as a pump inflates a balloon. As a balloon inflates, it takes less force to keep inflating because the walls thin as they stretch.

Furthermore, repeated wall stretching limits a balloon’s lifecycle. These are all factors a production facility may have to accommodate in a product quality assurance test. Using DewesoftX, we accommodated this by leveraging our extensive math suite and a range of formulas to allow variation from cycle to cycle.

Intelligent control using limit switches and TEDS sensors

Control is handled through a series of limit switches providing a digital signal (high or low) to a digital input (DI) channel on the Dewesoft hardware. This DI is then used by our Sequencer tool to determine when the carriage reaches the ends of its travel. When this occurs, a digital out (DO) is used to control a series of relays to stop the motor, change its direction of travel, and then turn it back on.

Similar logic is used to control the air pump motors. An analog input channel is used to read pressure from a pressure transducer mounted to the air manifold. This pressure transducer contains a TEDS chip, allowing the user to simply plug-and-go instead of manually entering the sensor’s calibration.

In addition to saving time, the TEDS interface and the DewesoftX sensor database prevent errors by automating calibration data entry.

At the center of the demonstrator is a Dewesoft IOLITE DAQ and control system. IOLITE is intended for precisely this kind of real-time control and data acquisition system. It is compatible with virtually all sensors and features the digital input and output lines needed to control other devices and read their operational states.

For more information on Automating Testing Procedures with the DewesoftX Sequencer: The Balloon Lift-off Demonstrator talk to Dewesoft UK Ltd