Add My Company

Add My Company

When it comes to technical installations, it's crucial to consider not only the technical aspects but also the housing involved. Outdoor setups, in particular, require careful attention to ensure that the housing can withstand the test of time and meet expectations.

Since these requirements often arise from the interaction between the environment and the installation, effective communication between the user and the builder/installer is vital. Special operating conditions such as exposure to UV light, corrosive elements, vapours, salt, electromagnetic interference, vibrations, shocks, or even earthquakes must be taken into account.

In this blog post, we'll delve into the choice of materials for outdoor enclosures, corrosion protection, and finishes. We'll also explore the construction of the outer box in terms of mechanical load and impact class IK.

Aluminium or Alternative Materials

While the various standards for outdoor installations don't explicitly specify the material for a protective enclosure, they do emphasise selecting a material suitable for the intended application. If the normal operating conditions are deviated from, information exchange is necessary. After all, the right choices can only be made if it is known what needs to be taken into account. Too often decisions are still made on the basis of assumptions, as a result of which the result can be disappointing. In the event of special operating conditions, a list follows in which you must choose what applies to you. It is better if this is specified in the program of requirements.

Aluminium is a popular choice as the base material for typical outdoor enclosures. It's not just because aluminium is relatively lightweight and easy to work with, but also because it boasts excellent corrosion resistance. Moreover, due to aluminium's conductivity, with the right additional measures, it can provide protection against electromagnetic interference in high-frequency fields. These properties offer significant advantages over alternatives like plastic or stainless steel in outdoor applications.

Despite the described positive properties of aluminium, the material is almost always provided with a UV-resistant coating to ensure long-term protection. The standard that addresses the conditions of electrotechnical products also indicates that the correct operation must be guaranteed in the long term. Effects that can influence this must be resisted by the right choice of housing.

Coating Requirements

While aluminium possesses inherent corrosion-resistant properties, it can still succumb to "white rust" under specific environmental conditions. In typical outdoor enclosures, a slight formation of "white rust" should be addressed, although it typically doesn't lead to significant problems. A gentle rub with a lightly oiled cloth can prevent this form of oxidation.

While aluminium possesses inherent corrosion-resistant properties, it can still succumb to "white rust" under specific environmental conditions. In typical outdoor enclosures, a slight formation of "white rust" should be addressed, although it typically doesn't lead to significant problems. A gentle rub with a lightly oiled cloth can prevent this form of oxidation.

Outdoor enclosures often come with a protective coating applied at the factory, available in the user's desired colour. This coating must be UV-resistant to prevent chalking. The requirements for UV resistance are detailed in various relevant standards. Minor damages like scratches can be easily repaired by removing oxidation on-site, thoroughly cleaning the surface, and applying the appropriate repair paint. In cases of extreme corrosion or excessive UV radiation, where significant damage occurs, the paint layer must be completely repaired using the manufacturer's prescribed paint.

Protection Class

When it comes to outdoor enclosures, ensuring the right level of protection is crucial. The environment in which the enclosure is placed plays a significant role in determining the appropriate IP (Ingress Protection) class. For instance, if your enclosure is exposed to fine sand and strong winds, it will have different sealing requirements compared to one located in a residential area. IP protection classes are determined through laboratory testing based on relevant standards. However, it's essential to accurately translate these standards to the specific installation location to maintain long-term protection.

will have different sealing requirements compared to one located in a residential area. IP protection classes are determined through laboratory testing based on relevant standards. However, it's essential to accurately translate these standards to the specific installation location to maintain long-term protection.

In addition to the IP protection class, the enclosure's resistance to external impact needs to be assessed. The impact resistance is measured using an IK value, but it should always be considered in conjunction with the corresponding IP protection class. Any damage to the seals caused by external impact directly affects the IP protection class. If the seals near the edges are damaged, they must be replaced immediately. However, damage to the seals outside the pressure edges may still maintain sufficient sealing action. To prevent seal damage due to freezing, you can use common agents such as talcum powder, petroleum jelly, or wax.

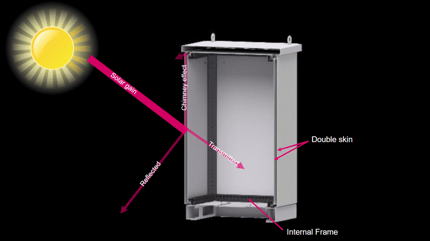

Double-Walled Construction

When installing an enclosure outdoors, it's important to consider the effects of solar radiation and heat build-up. Throughout the day, the angle of the sun's rays changes, resulting in varying degrees of heat on different sides of the enclosure. Direct and diffuse solar radiation can cause excessive heating, particularly in single-walled enclosures. However, a double-walled ventilated construction reduces the impact of solar radiation by creating a chimney effect. This means that less heat enters the enclosure, resulting in temperature differences of up to 20°C compared to a single-walled enclosure. Additionally, the stagnant air within the double wall acts as insulation, limiting cooling and reducing condensation. These properties not only affect heat dissipation but also contribute to energy savings by reducing the need for additional heating.

When installing an enclosure outdoors, it's important to consider the effects of solar radiation and heat build-up. Throughout the day, the angle of the sun's rays changes, resulting in varying degrees of heat on different sides of the enclosure. Direct and diffuse solar radiation can cause excessive heating, particularly in single-walled enclosures. However, a double-walled ventilated construction reduces the impact of solar radiation by creating a chimney effect. This means that less heat enters the enclosure, resulting in temperature differences of up to 20°C compared to a single-walled enclosure. Additionally, the stagnant air within the double wall acts as insulation, limiting cooling and reducing condensation. These properties not only affect heat dissipation but also contribute to energy savings by reducing the need for additional heating.

Outdoor enclosures are available in both single-walled and double-walled versions. While the choice of construction does not directly relate to the aforementioned protection class, a double-walled enclosure offers advantages due to the separation of the internal and external environments. An intermediate option, featuring a single-walled body with a double-walled roof, provides benefits for air conditioning purposes. The space between the double-walled roof can accommodate a fan or ventilation grille with the same high IP protection class as the enclosure. This setup allows for heat dissipation within the inner housing while providing an additional layer of insulation against direct solar radiation and associated heating.

For more information on Can Corrosion Threaten Your Aluminium Outdoor Enclosure? talk to Rittal Ltd